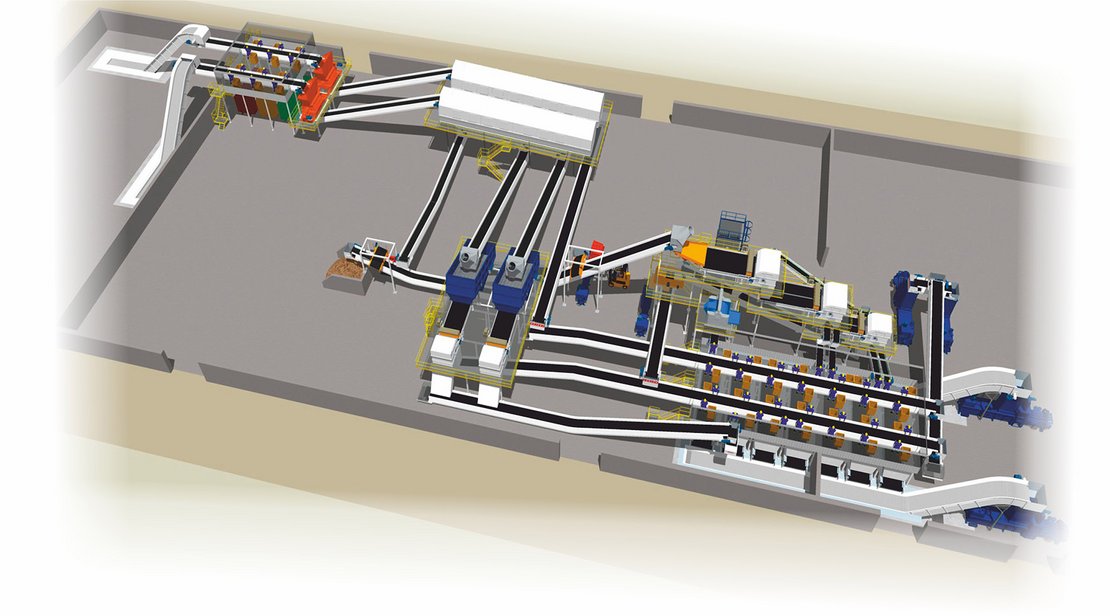

Municipal solid waste sorting line with 50,000 tons per year output

Waste sorting stations are for sorting a wide variety of industrial and domestic wastes. Lines with 50,000 tons output have 5 implementation versions.

Description

Waste sorting stations are for sorting a wide variety of industrial and domestic wastes. Lines with 50,000 tons output have 5 implementation versions.

Description of the complex

Version I - with municipal solid waste “leftovers” compaction with a waste compactor.

This system is used for the municipal solid waste stations that are far from waste burial site. Depending on transportation distance, waste compactor can be equipped with an automatic container change system.

Version II - without municipal solid waste “leftovers” compaction.

The line is recommended to be used directly at the municipal solid waste burial site.

Version III – complete with a reversible conveyor.

Used at the stations that are up to 3 km away from the waste burial site; the use of the reversible conveyor allows the line to run non-stop when the containers are changed. The reversible conveyor also performs the storage function.

Version IV - complete with a municipal solid waste “leftovers” hopper.

Is used for the stations situated at a small distance of up to 1 km from the waste burial site. The waste hopper allows to fill the container without stopping the line. The waste hopper is filled within up to 10-15 minutes. Discharge conveyor item 7 can also perform the storage function.

Version V - complete with a press for the municipal solid waste “leftovers”.

Is used for the stations situated at a significant distance from the waste burial site. The station body must be heated and must have a filtration system. The equipment can work non-stop when the press maintenance is performed, as it is equipped with a reversible conveyor.

Version I - with municipal solid waste “leftovers” compaction with a waste compactor.

Line components:

- Receiving apron conveyor L=23 m, B=1,2 m

- Sorting belt conveyor L=20 m, B=1,2 m

- Press feed apron conveyor L=20 m, B=1,2 m

- Vibrating table

- Ferrous metal separator

- Recycled materials compactor (optional, to be agreed upon with customer)

- Compactor

- Sorting ramp 1 L=21 m, B=5,0 m, H=3,0 m

- Sorting ramp 2 L=6,0 m, B=5,0 m, H=3,0 m

- Climatic cabin L=15,0 m, B=5,0 m, H=3,0 m

- Operator’s cabin

Version II - without municipal solid waste “leftovers” compaction.

Line components:

- Receiving apron conveyor L=23 m, B=1,2 m

- Sorting belt conveyor L=20 m, B=1,2 m

- Press feed apron conveyor L=20 m, B=1,2 m

- Vibrating table

- Ferrous metal separator

- Briquetting compactor (optional)

- Open-type container V=25 m3

- Sorting ramp 1 L=21 m, B=5,0 m, H=3,0 m

- Sorting ramp 2 L=6,0 m, B=5,0 m, H=3,0 m

- Climatic cabin L=15,0 m, B=5,0 m, H=3,0 m

- Operator’s cabin

Version III – complete with a reversible conveyor.

Line components:

- Receiving apron conveyor L=23 m, B=1,2 m

- Sorting belt conveyor L=20 m, B=1,2 m

- Press feed apron conveyor L=20 m, B=1,2 m

- Vibrating table

- Ferrous metal separator

- Briquetting compactor (optional)

- Open-type container V=25 m3

- Sorting ramp 1 L=21 m, B=5,0 m, H=3,0 m

- Sorting ramp 2 L=6,0 m, B=5,0 m, H=3,0 m

- Climatic cabin L=15,0 m, B=5,0 m, H=3,0 m

- Operator’s cabin

- Reversible belt conveyor L=11 m, B=1.2 m

Version IV – complete with a municipal solid waste “leftovers” hopper.

Line components:

- Receiving apron conveyor L=23 m, B=1,2 m

- Sorting belt conveyor L=20 m, B=1,2 m

- Press feed apron conveyor L=20 m, B=1,2 m

- Vibrating table

- Ferrous metal separator

- Briquetting compactor (optional)

- Belt conveyor discharging the waste “leftovers” L=21 m, B=1.2 m

- Sorting ramp 1 L=21 m, B=5,0 m, H=3,0 m

- Sorting ramp 2 L=6,0 m, B=5,0 m, H=3,0 m

- Climatic cabin L=15,0 m, B=5,0 m, H=3,0 m

- Operator’s cabin

- Waste hopper

- Belt conveyor support for the waste “leftovers” and the waste hopper

Version V – complete with a municipal solid waste “leftovers” press.

Line components:

- Receiving apron conveyor L=23 m, B=1,2 m

- Sorting belt conveyor L=20 m, B=1,2 m

- Press feed apron conveyor L=20 m, B=1,2 m

- Vibrating table

- Ferrous metal separator

- Briquetting compactor (optional)

- Open-type container V=25 m3

- Sorting ramp 1 L=21 m, B=5,0 m, H=3,0 m

- Sorting ramp 2 L=6,0 m, B=5,0 m, H=3,0 m

- Climatic cabin L=15,0 m, B=5,0 m, H=3,0 m

- Operator’s cabin

- Reversible belt conveyor L=16 m, B=1,2 m,

- Reversible belt conveyor support

- Press feed apron conveyor L=10 m, B=1,2 m