MSW (Municipal Solid Waste) contains significant amounts of recyclable components. To enhance the quality of source-segregated waste, manual sorting of specific materials is employed. This enables effective recovery of valuable fractions such as paper, plastics, glass, and metals. Metals are often separated using magnetic and eddy current separation methods.

The technological process operates as follows:

Waste Receiving & Preliminary Inspection. Arriving waste trucks unload mixed waste onto a covered platform. Workers inspect the MSW stream to:

- Remove bulky items (furniture, appliances, tin-coated containers, etc.).

- Extract hazardous waste (batteries, electrical devices, etc.).

Primary Processing. A tractor or front-end loader feeds waste into the bag breaker hopper. Mixed waste is then conveyed via an apron conveyor to pre-sorting cabins for:

- Extraction of large fractions before screening.

- Recovery of specific recyclable fractions.

Screening Stage. Waste is discharged into a screener (drum, disc, or dynamic type, depending on capacity/multitasking requirements) to:

- Screen fine fractions (food waste, stones, street sweepings, ceramics, etc.).

- Loosen the waste mass.

- Split the main stream into 3 size-based fractions (only for triple-drum screeners).

- Deliver waste in a single layer to the sorting conveyor.

Screened undersize material is diverted to containers via chute conveyors.

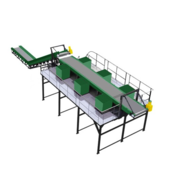

Main Sorting Conveyor. Remaining mixed waste moves to the main sorting conveyor with dedicated recovery stations. Operators at each station manually recover:

- Cardboard, paper, textiles, PET bottles, polyethylene, and glass (dropped into chutes).

- Ferrous metals (cans, tubes, bottles) via overhead magnetic separator.

- Non-ferrous metals via eddy-current separator.

Recyclables Processing. Recovered materials (except glass/ferrous metals) are pushed by a loader into a pit, then conveyed to a wire-strapping baling press.

Residue Handling. Residual waste (non-recyclable fraction) is conveyed via apron conveyor to:

- A compactor, stationary press, or container (customer’s choice) for baling (if pressed) and landfill transport.

Facility Features.

Sorting cabins include: forced ventilation, firefighting equipment, and bactericidal lamps.

Centralized electric control system: operated from main/local control panels (with individual motor drives). local panels allow on/off switching and mode adjustments, emergency stop buttons on all equipment.

Conveyor systems: frequency-controlled drive motors (speed adjustable between 10–20 m/min). Speed adjusted by operators based on waste composition/volume.

| The sorting line is designed and configured based on the Customer's engineering specifications or technical requirements. |

|---|