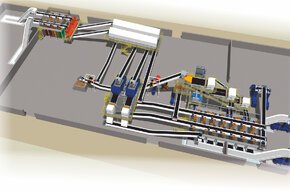

Municipal solid waste sorting line with 100,000 tons per year output

Waste sorting stations are designed to sort a wide variety of industrial and domestic wastes. Lines with 100,000 tons output have 3 implementations versions.

Description

Waste sorting stations are designed to sort a wide variety of industrial and domestic wastes. Lines with 100,000 tons output have 3 implementations versions.

Description of the complex

Version I - without municipal solid waste “leftovers” compaction.

Sorting lines with this set of equipment are used at stations located directly at the municipal solid waste burial site.

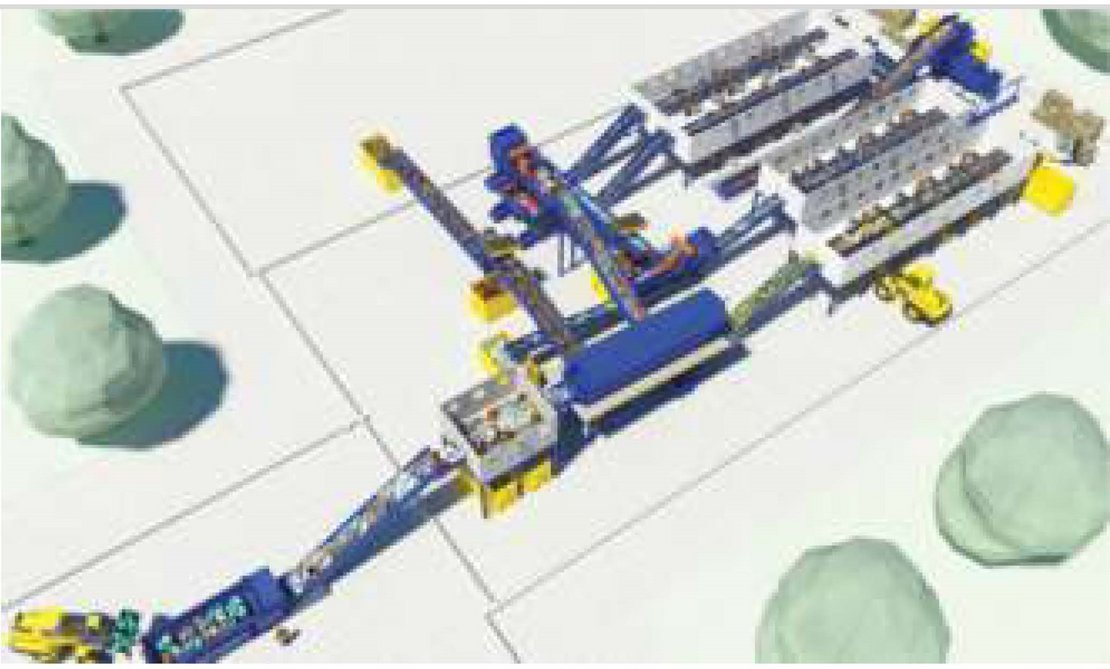

Version II - complete with a municipal solid waste “leftovers” compactor.

Is used for municipal solid waste sorting stations located both at the burial site and far from it. Waste “leftovers” compaction in the compactor allows to reduce the volume of the buried municipal solid waste, increases the map density, protects the burial site from burning. In case of the long transportation distance to the waste burial site the compactor can be equipped with an automatic compaction container change system.

Version III – complete with a municipal solid waste “leftovers” press.

Is used for the stations located at a considerable distance from the waste burial site. The station site must be heated and must have a leachate removal system. Thanks to being equipped with a reversible conveyor the equipment can work non-stop when the press maintenance is performed. In order to protect the trommel screen, the line is additionally equipped with a pre-sorting cabin for selection of the large fraction municipal solid waste.

Version I - without municipal solid waste “leftovers” compaction.

Line components:

- Receiving apron conveyor L=24,5 m, B=1,2 m

- Main sorting belt conveyor L=20 m, B=1,2 m

- Press feed apron conveyor L=20 m, B=1,2 m

- Pre-sorting belt conveyor L=10,2 m, B=1,2 m

- Transfer belt conveyor L=5,0 m, B=1,2 m

- Small fraction waste discharge belt conveyor L=12 m, B=1,2 m

- Briquetting compactor (optional)

- Ferrous metal separator

- Drum separator (optional)

- Main sorting ramp L=21 m, B=6,0 m, H=2,6 m

- Pre-sorting ramp L=12,5 m, B=6,0 m, H=5,0 m

- Main sorting climatic cabin L=11,0 m, B=6,0 m

- Pre-sorting climatic cabin L=6,5,0 m, B=6,0 m

- Compactor

Version II - complete with a municipal solid waste “leftovers” compactor.

Line components:

- Receiving apron conveyor L=24,5 m, B=1,2 m

- Main sorting belt conveyor L=20 m, B=1,2 m

- Press feed apron conveyor L=20 m, B=1,2 m

- Pre-sorting belt conveyor L=10,2 m, B=1,2 m

- Transfer belt conveyor L=5,0 m, B=1,2 m

- Small fraction waste discharge belt conveyor L=12 m, B=1,2 m

- Briquetting compactor (optional)

- Ferrous metal separator

- Drum separator (optional)

- Main sorting ramp L=21 m, B=6,0 m, H=2,6 m

- Pre-sorting ramp L=12,5 m, B=6,0 m, H=5,0 m

- Main sorting climatic cabin L=11,0 m, B=6,0 m

- Pre-sorting climatic cabin L=6,5,0 m, B=6,0 m

- Compactor

- Reversible belt conveyor L=16,0 m, B=1,2 m

Version III – complete with a municipal solid waste “leftovers” press.

Line components:

- Receiving apron conveyor L=24,5 m, B=1,2 m

- Main sorting belt conveyor L=20 m, B=1,2 m

- Press feed apron conveyor L=20 m, B=1,2 m

- Pre-sorting belt conveyor L=10,2 m, B=1,2 m

- Transfer belt conveyor L=5,0 m, B=1,2 m

- Small fraction waste discharge belt conveyor L=12 m, B=1,2 m

- Briquetting compactor (optional)

- Ferrous metal separator

- Drum separator (optional)

- Main sorting ramp L=21 m, B=6,0 m, H=2,6 m

- Pre-sorting ramp L=12,5 m, B=6,0 m, H=5,0 m

- Main sorting climatic cabin L=11,0 m, B=6,0 m

- Pre-sorting climatic cabin L=6,5,0 m, B=6,0 m

- Reversible belt conveyor L=16,0 m, B=1,2 m

- Press feed apron conveyor L=17,0 m, B=1,2 m