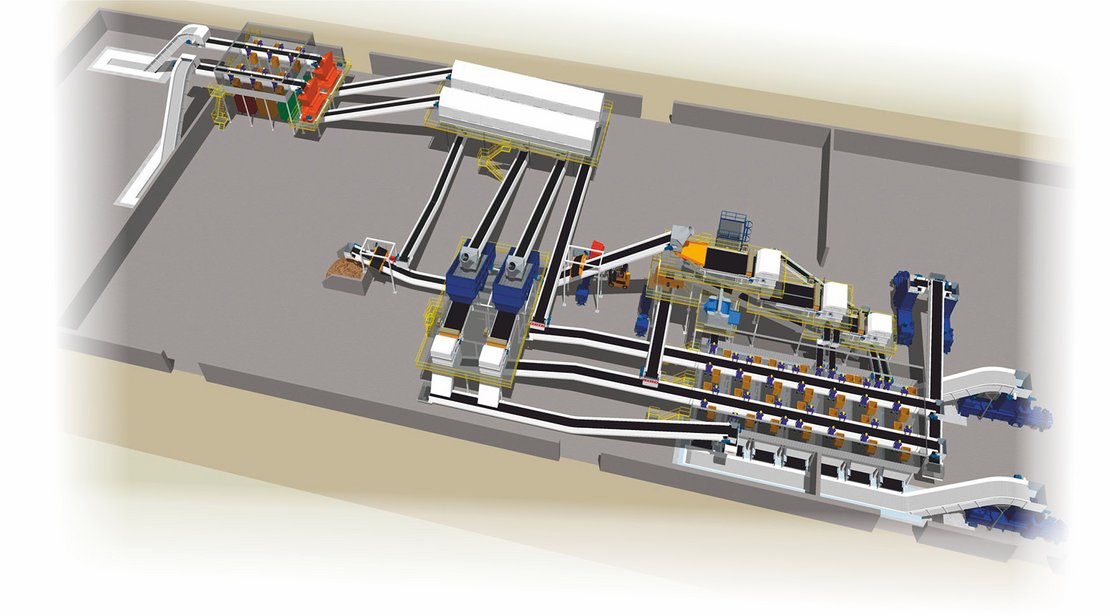

MSW sorting line, capacity 20TPH

Processing flow: The feeding by loader or grab → Hydraulic primary shredder (bag breaking and primary shredding) → Manual sorting plaftform (pick out recyciables) → Trommel screen (remove small debris and some organic s for landfill) → Magnetic separator (separate the ferrous metal) → Eddy current separator (separate non ferrous metals) → Windshifter (remove heavy debris for landfill) → Double-shaft fine shredder (output around 50mm RDF)

Description

- Raw material MSW (without heavy metal and stones:

- Final product: most around 50m m RDF

MSW sorting line key components

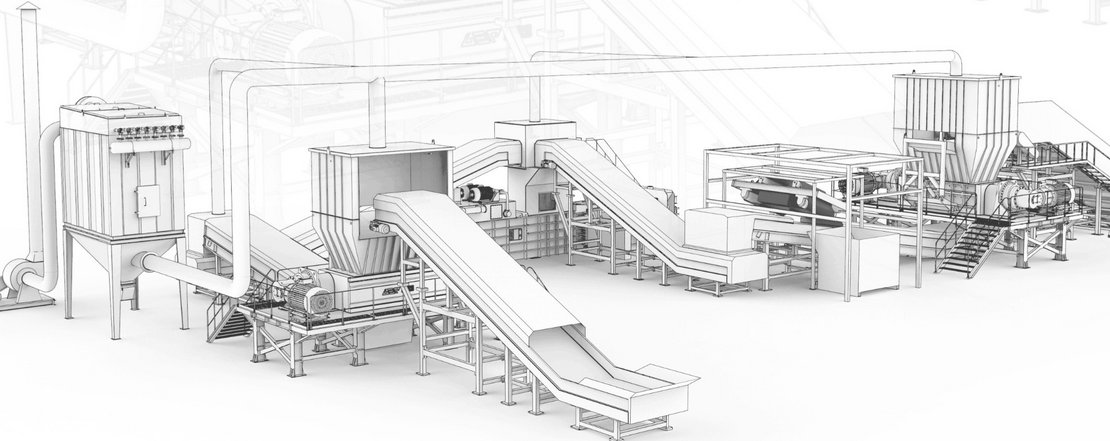

Primary two shaft shredder is one of the main shredding equipment with high production efficiency for solid waste shredding, which is mostly used in the first process of various solid waste shredding. The material is treated by shearing, tearing and pulling by the interaction between the moving cutters and the middle counter cutters. It has the characteristics of large crushing force, high output, low noise and good stability. Usually used in various solid waste crushing treatment, domestic waste crushing treatment, waste volume reduction and other fields.

- Main Applications:

Solid waste shredding; - Metal recycling (light steel, aluminum and m agnesium parts shredding);

- Bulky waste shredding process;

- Bale/Briquette breaking;

- Waste incineration power plant;

- RDF (refuse derived fuel) crushing;

- Landfill materials processing.

Trommel screen is a kind of screening equipment of grading treatment according to the particle size of materials, the structure is strong, the sieve rate is high, the sieve hole is not easy to block, and the output and reliability of the screening system are improved. The whole equipment system adopts an effective fully sealed structure, which is equipped with interface with dust removal and deodorization system, and does not raise dust and pollute the environment

It is mostly used in municipal solid waste, landfill waste, industrial solid waste, construction waste, mining, power plant, building materials, metallurgy and other industries.

Non ferrous metal separator, also known as eddy current separator, is mainly used to separate copper, aluminum and other non ferrous metals from indus trial waste and domestic waste. It can be widely used in the fields of waste disposal, waste automobile dismantling and recycling, waste electrical appliances recycling, and material treatment of non fer rous metal processing industry.

Windshifter /separator, also known as drum density separator, uses the controllable air flow as th e separation medium, under the action of the controllable air flow, the selected materials can be separated according to the density and particle size.

The air flow can take the lighter materials (such as paper, plastic bags, films, etc.) upward or horizontally to a far place, while the heavy materials fall because the updraft cannot support them, or because the inertia throws a relatively short distance in the horizontal direction. Therefore, the wind separation process is based on the settlement ru le of matter in the air, so as to achieve the purpose of classification.

Fine shredder is also called single/double-shaft shredder. It uses the interaction of movable cutter heads and fixed cutters to tear, cut and extrude the material into small size; at the same time controls the output size by its screen mesh. Fine shredder is used for processing all kinds of solid waste. Materials can be shredded to small pieces one-time, so it is widely used in the field of resource regeneration, RDF (refuse derived fuel) making, refuse volume reduction and etc. Fine shredder has the features of small output size, screen mesh changeable, wide applicability of materials and high efficiency.

Main Applications: municipal waste, plastic, industrial waste, rubber, waste fabrics, biomass and other solid waste

Intelligent control cabinet . Siemens PLC control cabinet & touch screen operation system

MSW sorting line includes:

- Hydraulic primary shredder, 160KW - 1set

- Belt conveyor (width 1400mm, length 12m), 4KW - 1set

- Trommel screen, 22KW - 1set

- Belt сonveyor (width 1000mm, length 6m), 2.2KW - 3sets

- Belt conveyor w(idth 1200mm, length 6m), 3KW- 1set

- Belt conveyor (width 1200mm, length 8m), 3KW - 1set

- Magnetic separator, 4KW - 1set

- Vibrating feeder, 2*3KW - 1set

- Eddy current separator, 11KW - 1set

- Belt conveyor (width 1000mm, Length 14m(, 3KW - 1set

- Windshifter, 45KW - 1set

- Belt conveyor (width 1000mm, length 15m), 3KW - 1set

- ;Secondary shredder, 2*110KW - 1set

- Belt conveyor (width 1000mm, length 10m), 2.2kW - 1set

- Manual sorting plaftform (width 1200mm, length 16m,10 stations), 5.5KW - 1set

- Intelligent control cabinet: intelligent monitoring, Siemens PLC system with touch screen, integral control - 1set