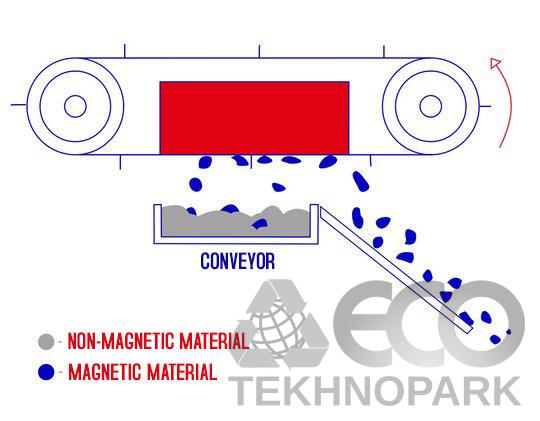

A self-cleaning overhead magnetic separator (suspended magnet) designed for extracting large ferrous metal inclusions from a stream of municipal solid waste (MSW) moving on a conveyor.

Parameters of magnetic separators of ERG SMPA series for MSW sorting:

- Extended-length magnetic system based on permanent magnets for superior reach and strength.

- Effective ejection of the magnetic fraction beyond the conveyor belt for clean separation.

- Deep magnetic field penetration with a recovery depth of up to 350 mm.

- High lifting capacity, capable of extracting ferrous metal objects weighing up to 30 kg.

- Reliable components from leading global manufacturers ensure durability and uptime.

- Heavy-duty three-layer conveyor belt with a reinforced insert for long service life.

- Fully automatic self-cleaning operation for continuous, unmanned processing.

- Universal mounting solution for easy integration into any existing sorting line.

- Compatible with mobile shredders and crushers; can be equipped with a hydraulic motor drive for standalone applications.

- EAC Declaration of Conformity with TR CU requirements.

| Model | SMPA 1000 for MSW | SMPA 1200 for MSW | SMPA 1400 for MSW |

|---|

| Magnetic system working width, mm | 1000 | 1200 | 1400 |

| Recovery depth*, mm | up to 350 | up to 350 | up to350 |

| Electric Motor power, kW | 3 | 3 | 3 |

| *depends on specific installation settings | | | |