RDF (Refuse Derived Fuel), also known as solid recovered fuel, is a processed waste-derived fuel containing high-energy components including plastics, paper products, cardboard, textiles, rubber materials, leather, wood, and other combustible waste fractions.

RDF Fuel Specifications:

- Calorific value: 20,000 ± 2,000 kJ/kg

- Particle size: ~20-25 mm

- Hazardous components: Strictly controlled below permissible limits

- Energy equivalent: 1.7 kg RDF = 1 m³ of natural gas

Industrial Applications:

- RDF serves as primary or supplementary fuel in:

- Cement kilns

- Power plants (CHP)

- Metallurgical furnaces

Cement Industry Case Study. Cement production requires extreme temperatures (>2000°C) with substantial energy inputs:

- Traditional fuels: 60-130 kg of heavy fuel oil (or equivalent gas) + 105 kWh electricity per ton of cement

- Energy costs: Up to 40% of total production expenses

RDF implementation benefits:

- Replaces 30-60% of natural gas in operational kilns

- Reduces cement production costs

- Maintains product quality standards

Environmental Advantages vs MSW Incineration. Cement kilns' ultra-high temperatures (~1700°C):

- Virtually eliminate harmful emissions

- Outperform waste incineration plants in emission control

- Achieve complete combustion of organic compounds

Production Requirements:

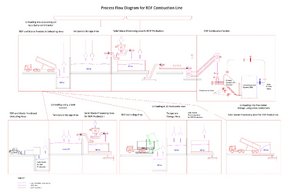

Waste Preprocessing:

- Essential for homogenizing mixed MSW into RDF feedstock

- Requires advanced sorting systems for consistent quality

Automated Sorting Advantages:

- Optical scanning technology delivers: 98% material recovery accuracy, exclusion of hazardous components (e.g., chlorinated materials)

Superior to manual sorting in:

- Throughput (10M identifications/second)

- Final RDF purity

Implementation Recommendation

Retrofitting existing MSW sorting facilities with automated systems:

- Ensures RDF meets cement industry specifications

- Optimizes recovery of high-calorific fractions

- Eliminates non-combustible contaminants