Finely dispersed municipal solid waste (MSW) drying technology

Biological dry stabilization is biological process of biodegradation (decomposition) of organic materials by the bacteria that live in the waste. During the decomposition of the organic materials by the bacteria heat is released as a part of metabolic process. The offered system with membrane coating, pressure aeration and other components use this natural process to effectively and reliably remove the moisture from the material being recycled (processed) in a controlled environment. As a result dry stabilization of the garbage (waste) occurs after the moisture removal and degradation (breakdown) of the organic matter.

Description

Description of the complex

Equipment for completing the project:

- membrane cover system

- aeration and air supply system

- monitoring and control system

- self-propelled compost turner

- membrane system

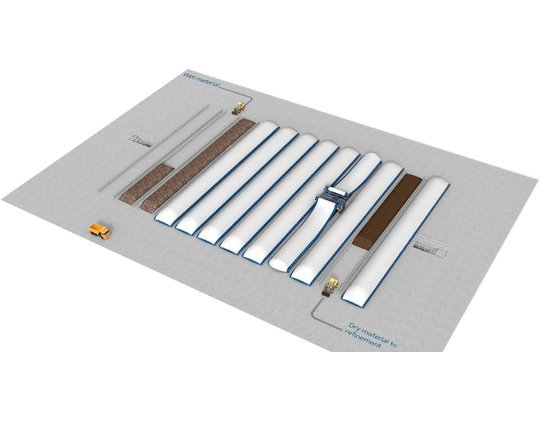

Dry stabilization begins with creation of a strip (line) of fresh finely dispersed municipal solid waste. Every working day 274 tons of municipal solid waste are delivered by dumpers (it is recommended) from certain dump sites to an appropriate place of a dry stabilization line. This could also be done with a wheel loader(s), but considering that the loading capacity of a dumper is 10 to 40 m3, transportation by a truck seems to be more efficient.

Within 2.5 days a line is filled by a wheel loader with a dump truck(s) that brings (bring) the incoming material to the lines.

The volume of each line is 685 tons (metric tons), which corresponds to 1370 m3 with the density of 0.5 t/m3 when a heap is formed. For denser waste the pile height can be less than that.

At the end of each working day during waste delivery time the line may be covered with a membrane in order to reduce gas emissions (discharge). Waste is covered by compost turner. After the line is filled within 2.5 days, waste is turned over for the first time, which contributes to the uniform air pore distribution in the material, making it a good start for the drying stabilization process.

Drying stabilization process takes 21 days, however, a line is filled within 25 days (2.5 days for the line to be filled with waste, 21 days for stabilization, 1 day for the stabilized waste to be removed). Before stabilized waste removal the turner goes along the line once more and removes the covering. During this last turn waste lumps are broken and the stabilized waste is homogenized for effective screening (removal of the harmful substances) or subsequent shredding (is not necessary).

The countdown of the drying stabilization process days starts on the next day after the line is filled and ends the day before the waste is removed from the line.

During the process the waste is turned over 4 times on site with supplied self-propelled compost turner. The waste remains in the same place from the beginning to end, so it is expected that dump trucks will be used for moving input material to the appropriate strip (line).

Thanks to the use of membrane system with supplied self-propelled compost turner the time a heap in drying stabilization stays uncovered is reduced to the time necessary for waste filling or removal. Waste is turned over under the membrane, which reduces gas emissions and minimizes the impact of the weather conditions.

Waste can be filled, turned over and emptied (removed) at both sides of the line, which reduces excess mileage of the vehicles that pass the lines.

We should note such an important safety advantage as minimizing traffic volume on site; provided there is proper scheduling it is easy to avoid the vehicles’ trajectories crossing. Waste can be filled and removed at different sides of the line, and most of the time the turner is away from these maneuvering areas.

Technical data

| Input material | Small-fraction municipal solid waste not exceeding 100 mm - 100,000 t/year |

| Input characteristics | Biogenic organic content not less than 40% of the dry matter |

| Input capacity | 274 tons/day, up to 365 days per year |

| Output density | In tossed (heaped) form - 0.5 tons/m3 |

| Number of strips (lines, passways) | 10 (length: 100 m, width: 6 m, height of pile: 2,6 m, volume: 1370 m3) |

| Output humidity | A) approximately 30% after the end of the stabilization phase, B) approximately 25% after the end of the stabilization phase |