Applicable materials

Waste rigid plastic material can be in many different conditions in terms of moisture, contamination, and rigid type, basically divided into the following families: bottles, chemical drums, HDPE milk bottles, industrial pipes, WEEE waste electrical equipment, ABS recycling, etc.

| Raw and processed materials |

|

| Finished product |

|

Advantages:

- Designed for rigid plastics with a wall thickness ranging from 1-25mm

- Minimizes the recycling water flow rate and evaporation losses

- Wear resistant design to maximize the consistent running of the system and minimize operational costs

- High speed washing system with corresponding speed according to material type

- The under-water force-washing paddle of the washing tank maximizes the washing efficiency

- Mechanical and thermal drying system minimizes the moisture of the end product

- High speed washing and drying can be set at suitable intensity to avoid over friction

- System automation to ensure components actions are linked, system capacity is maximized, and system protected against interfering material/

Process

After shredding, crushing, washing, and drying. The finished product could be fed into pelletizing systems to produce plastic pellets and create a bigger profit.

Unit introduction

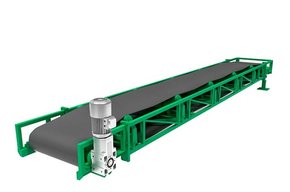

- Manual sorting belt conveyor. Function: manually sort out PVC bottle, labels, and other impurities.

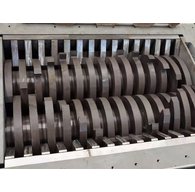

- Double shaft shredder break the material to 40-50mm.

- Belt conveyor and metal separator.

- Rinsing wash tank for PP PE bottle rinsing, metal, stone and other submerged impurities from the material.

- PTC wet wrusher for fine grinding.

- Floating washing tank: cleaning flakes and separating remained dirt and dust.

- Centrifugal dryer removes dirty water

- Hot & friction washer: rubbing clean the material and remove the foam and paint on the material surface by heating, used to add detergent and heat the flakes when high-speed friction cleaning, removing dirt.

- Zig-zag Air sorter: separate label dust from materials.

- Cleaning flakes and separating remained dirt and dust further

- Centrifugal dryer.

- Hot air dryer

- Floating washing tank. leaning flakes and separating remained dirt and dust further

- DCS intelligent recycling line control system

| Technical characteristics | | | | |

|---|

| Model | EPE/EPP500 | EPE/EPP1000 | EPE/EPP200 | EPE/EPP3000 |

| Capacity, kg/h | 500 | 1000 | 2000 | 3000 |

| Installation power. kW | 190 | 270 | 350 | 480 |

| Space, sq.m | 500 | 700 | 1000 | 1800 |

| Compressed air, cub.m/min | 0.5 | 0.5 | 0.5 | 0.5 |

| Water, cub.m | 2 | 2 | 4 | 6 |

Ленточный конвейер для ТКО

Ленточный конвейер для ТКО  Установка дробильная конусная модульная

Установка дробильная конусная модульная  Оптический сканер LI, NIR сканирование

Оптический сканер LI, NIR сканирование