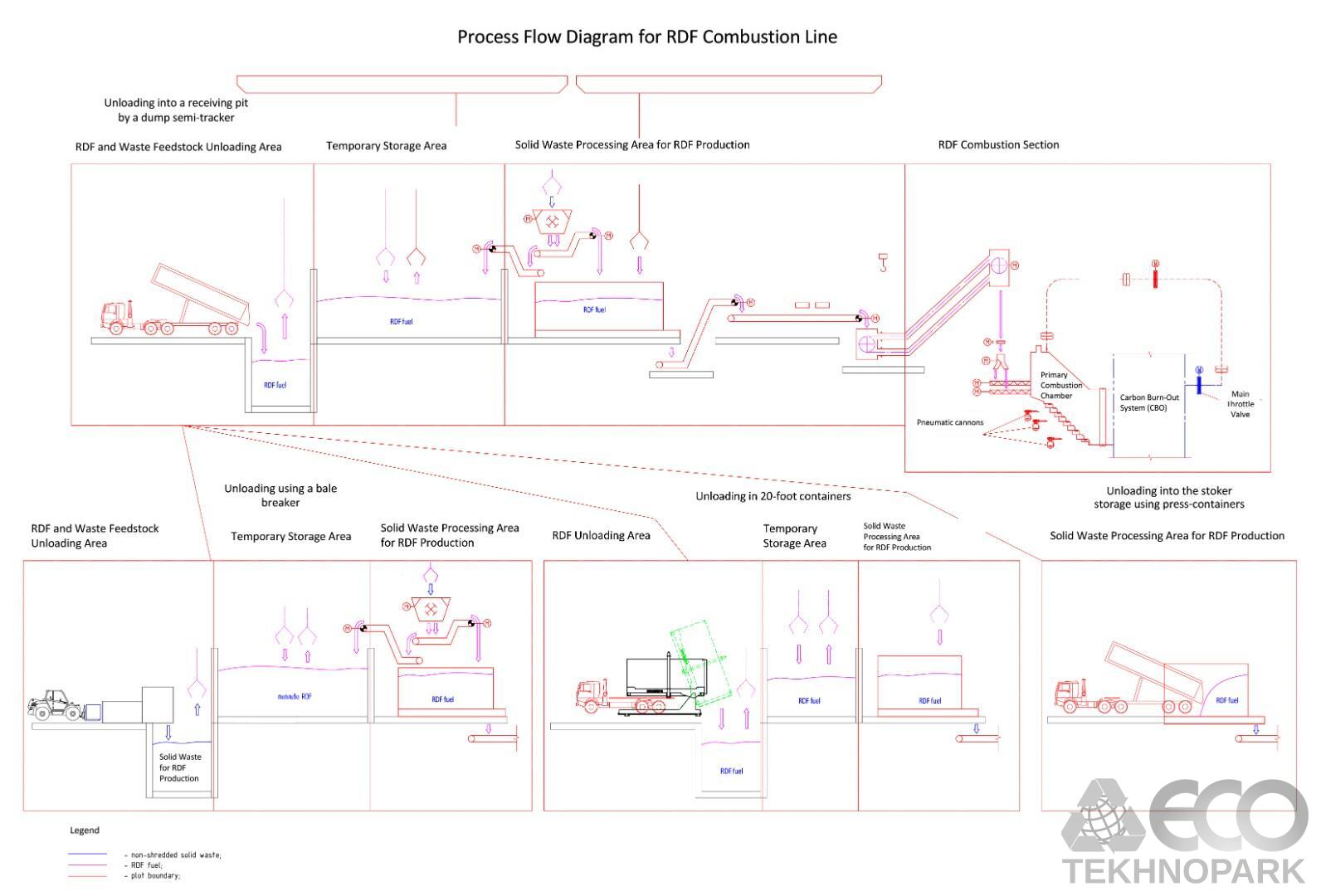

The construction of an RDF combustion line for cement production involves the use of an integrated stepped grate furnace (pre-combustion chamber), designed for the thermal utilization of alternative fuel (RDF fuel) with a low level of preparation. This line is integrated into the technological process of clinker production.

The composition of the proposed RDF combustion line and the basic specifications of the included equipment (the listed line components and equipment specifications are subject to change based on the specific technical requirements).

1. Temporary storage area

Double-girder bridge crane with grapple, purpose: hor handling and transporting RDF fuel and waste for RDF production.

2. RDF fuel and solid waste unloading area

- 20-foot container tippler, purpose: for unloading RDF fuel from 20-foot containers.

- Bale breaker / opener, purpose: for unpacking bales of solid waste for RDF production. Capacity: up to 10 tons/hour.

- Telescopic handler with a lift capacity of not less than 5520 kg.

3. Solid waste processing area for RDF production

- Live storage (stoker) hopper. purpose: for receiving and storing RDF fuel.

- Drag chain (scraper) Conveyor. purpose: for transporting RDF fuel from under the live storage hopper, capacity: 15 t/h.

- Universal single-shaft Shredder: purpose: for shredding solid waste for RDF production, output fraction Size: 50 mm.

- Reversible belt conveyor: purpose: for transporting shredded solid waste from under the shredder.

- Belt conveyor: purpose: for transporting RDF fuel from under the drag chain conveyor.

- Tubular (enclosed) conveyor: purpose: for transporting RDF fuel from under the belt conveyor.

4. RDF fuel combustion area

- Stepped grate pre-combustion:

- RDF fuel combustion capacity: 15 t/h.

- Maximum thermal output: 60 MW.

- Tertiary air supply to combustion zone: min. 1800 Nm³/h.

- Combustion products temperature: not less than 1100 °C.

- Stepped combustion mechanism with pneumatic pushers: 16 steps.

- Weight: not more than 120,000 kg.

- Shaftless screw conveyor (2 units):

- Purpose: feeds RDF fuel into the stepped grate furnace;

- Capacity: 7.5 metric tons/hour each.

- Electric flap valve: purpose: isolates hot air flow from the stepped furnace to the tubular conveyor.

- Tertiary air duct: purpose: supplies tertiary air to the stepped grate furnace.

- Hot air damper with electric actuator: purpose: regulates the volume of tertiary air supplied to the stepped grate furnace.

- Metallic expansion joint (3 units): purpose: compensates for thermal expansion in the tertiary air duct.

- Control System: purpose: remote control from the control room and local control for the stepped grate furnace operation.

- Enclosure Rating: IP54.

- Integration: Capable of integration into the plant's existing Automated Process Control System (APCS).

- Communication: Supports Profibus protocols.

| Name of parameter | Value |

|---|

| Requirement of the Line | Combustion of coarse-fraction and moist (up to 40% humidity) RDF fuel. |

| RDF fuel combustion capacity | at least than 15 tons per hour |

| Maximum thermal output: | 60 mW |

| Supply of tertiary air to the combustion zone | at least than 1800 m³/h |

| Multi-stage air distribution. | Yes |

| Moving parts inside the high-temperature zone. | No |

| Equipped with a grate with pneumatic shakers and air blast cooling. | Yes |

| Service platforms | Included |

| Access hatches and ports for cleaning and maintenance. | Included |

| Temperature of combustion products: | no less than 1100 °C |

| Combustion products | are fed into the pre-calciner in the tertiary air intake area |

| RDF fuel loading airlock system | feeds material into the combustion chamber via two screw conveyors, and includes an automatic fire suppressio system |