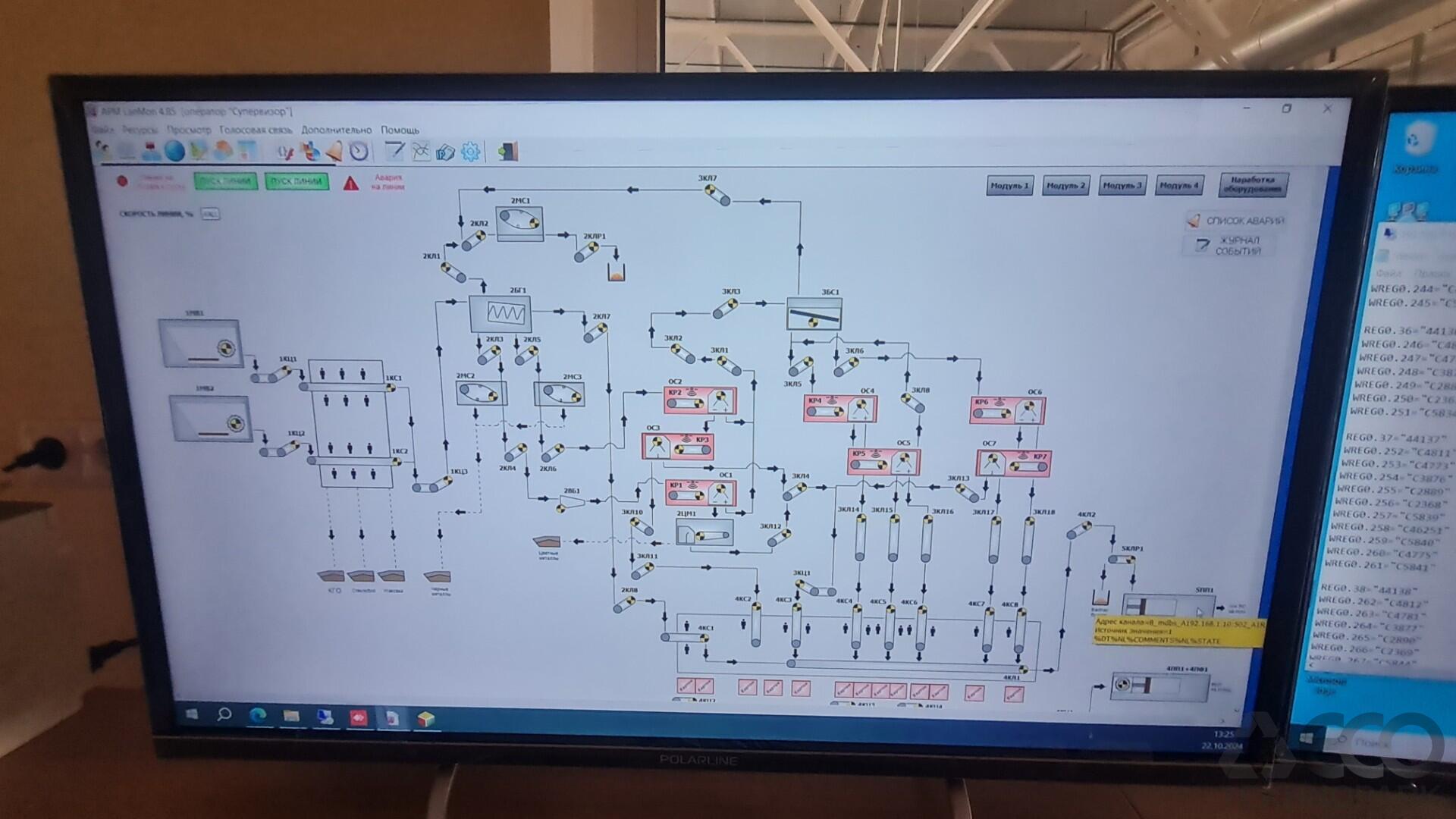

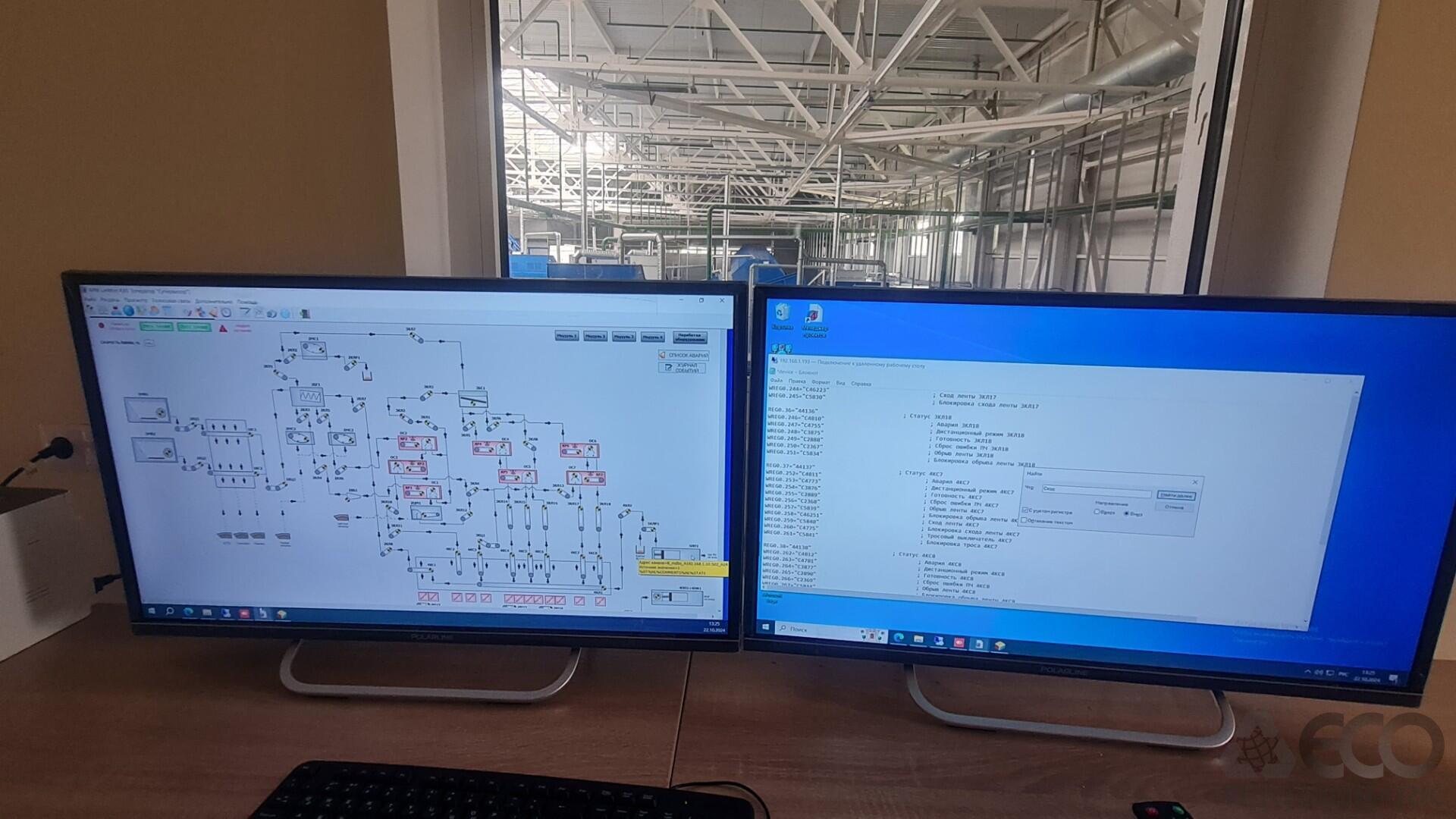

The Automated Control System (ACS) equipment complex provides centralized control for the entire automated waste sorting line. Individual equipment units feature their own control systems, which are fully integrated into the overall ACS.

The ACS functionality includes:

Real-time equipment operation monitoring.

- Conveyor belt tracking and automatic equipment shutdown upon misalignment.

- Monitoring of emergency rope pull switches and equipment stoppage upon activation.

- Data transmission from equipment operator panels (separators, bag breakers, balers, etc.) to the operator's workstation mimic diagram.

- Conveyor belt speed adjustment (on required conveyors).

- Support for standard communication protocols and signals: network protocol; discrete signals – "dry" contact; analog signals.

The ACS implements the following operational modes for process equipment control:

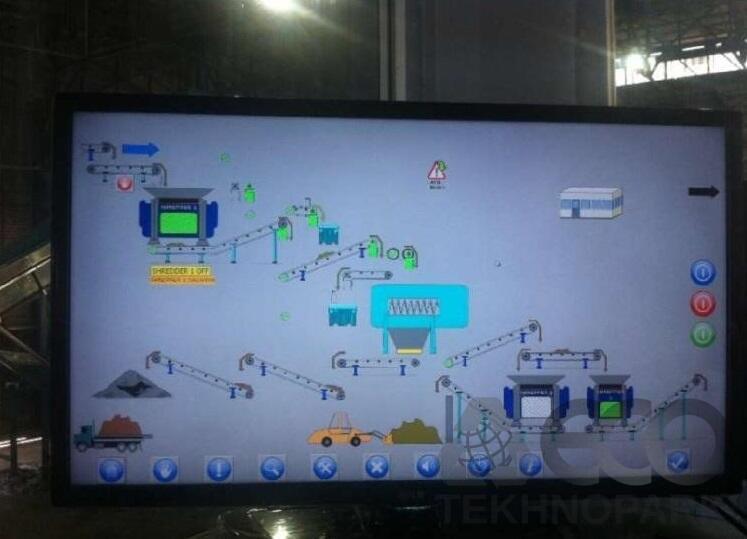

- Automatic Mode: Manages the control and regulation process according to established algorithms. Selected by the operator via settings on the workstation in the control room.

- Remote Control: The operator controls the drive (start/stop) using the mouse or keyboard at the workstation. Commands are executed via the ACS with safety and access level checks.

- Local Control: Drive control is possible using operator panels located directly near the actuators and units, with parameters displayed on the workstations in the control room.

Visualization of individual elements of the technological process is implemented in a logical sequence. The ACS features a self-diagnostic mode with fault alerts.

The overall automated control system is equipped with a control rack and a touch LCD control panel. It offers two operating modes: primary (from the control panel) and auxiliary (from the push-button controls). The system is fitted with frequency converters for each conveyor drive.

The ACS ensures the following functions:

- Soft start and stop.

- Conveyor speed adjustment.

- Overvoltage and undervoltage protection.

- Overload protection.

- Reverse operation for reversible conveyors (where required).

The system design includes:

- Drum rotation speed sensors.

- Belt misalignment sensors (on belt conveyors).

- A voltage surge monitoring system.

- A control panel ventilation and cooling system.

- Installation of converters and controllers at each station.

- Emergency stop buttons at the drive and tension stations.

- Limit switches on access hatches for rotating conveyor parts.

| Process control system (PCS/ACS) parameters | The system is designed and developed based on the specific configuration of the Waste Sorting or Processing Line. |

|---|