Willibald EP 5500 Shark Shredder delivers outstanding results in biomass preparation, composting processes, and biogas substrate production.

Thanks to its unique shredding system, the EP series machines can process diverse materials to meet specific requirements: green waste, biomass, old wood, pallets, bark, peat, and biogas substrates (e.g., sugar beet, potato, onion, carrot, manure, grass, and silage corn).

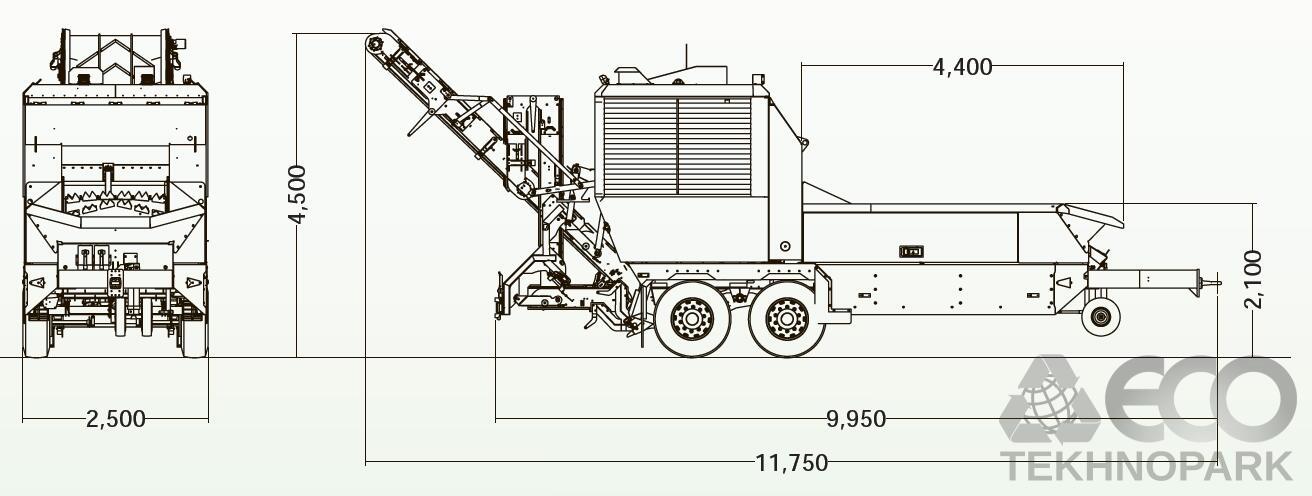

The EP 5500 Shark series features a specially extended conveyor belt. Increased discharge height optimizes operation in confined spaces and enables direct loading of container trucks. Integrated intelligent bending technology in the rubber discharge belt allows rapid positioning in three key configurations:

- Transport Position (overall machine length: 9.98 m)

- Service Position (providing unique access for maintenance tasks like chain, shaft, and basket screen replacements)

- Working Position

Depending on the input material and specific needs, the following configurations are available:

Shark I:

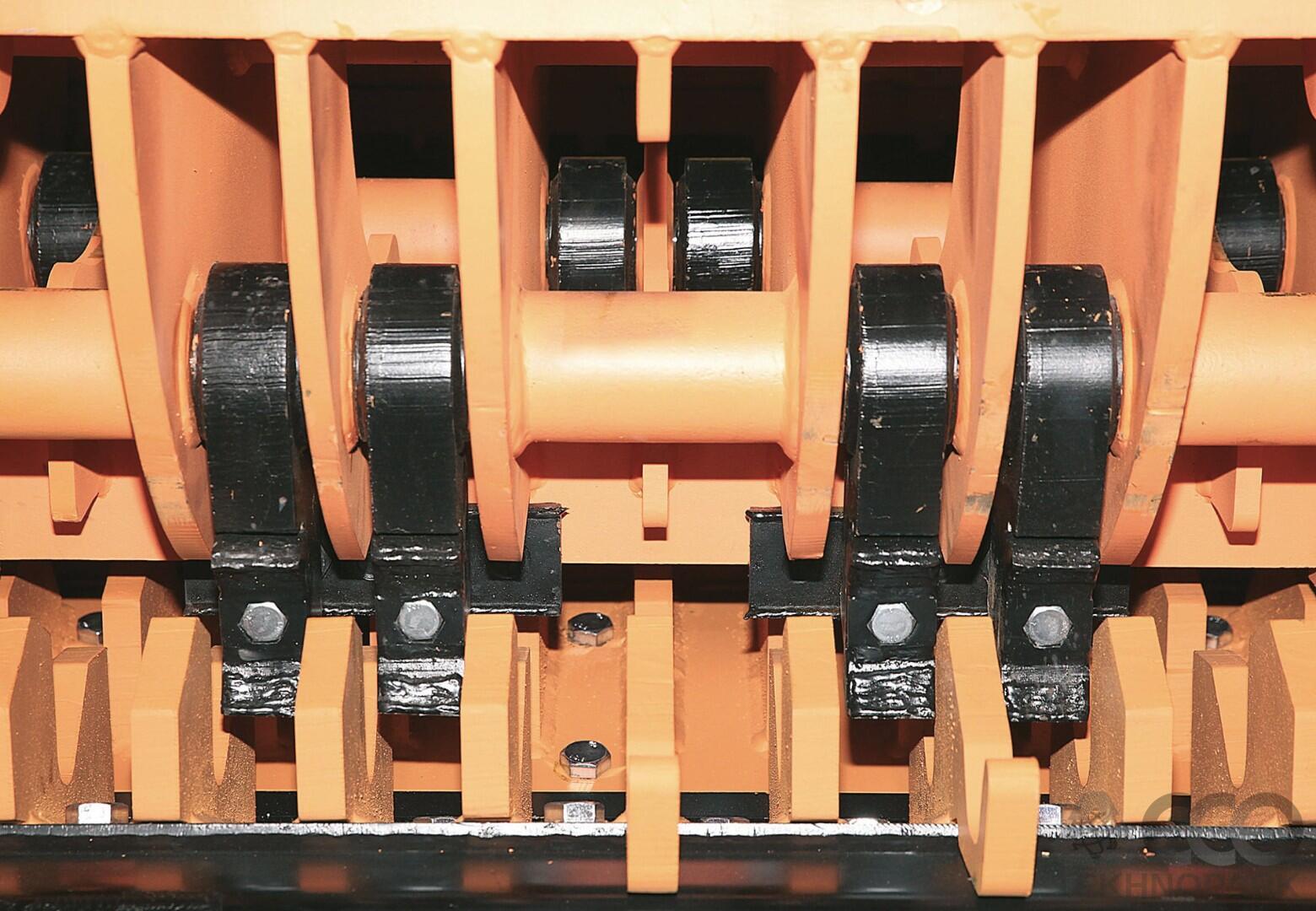

The shredding system utilizes a 48-blade rotor, further optimized for performance. Combined with the adjustable Willibald rake system, the 48 chains achieve the desired fraction size. Shark I is the ideal choice when small fraction size is required.

Shark II:

The powerful Shark II shredder features a rotor with 16 robust double chains equipped with an innovative system of 32 replaceable tips. Shark II is versatile equipment suited for processing various types of input materials.

Shark III - Biomass Processing Expert:

The latest Willibald EP 5500 Shark III model is equipped with a rotor featuring 12 heavy-duty double loops integrated with an advanced replaceable tip system. Depending on requirements, the system can operate with either 24 freely rotating hard-metal tips on one side or 12 (fixed) blades on the other. This model delivers exceptional results when processing biomass.

The Willibald EP 5500 Shark shredders represent the further development of the MZA series.

Additional options:

| Conveyor belt |

# |

° |

Conveyor belt;

The hydra is 4.5 m long and collapsible |

|

° |

| Magnetic Guide Roller |

|

° |

| Crawler Drive |

# |

° |

| Remote Control |

|

° |

| Central Lubrication |

|

° |

| hydr. Axle Extractor |

|

° |

| hydr. Support Wheel |

# |

° |

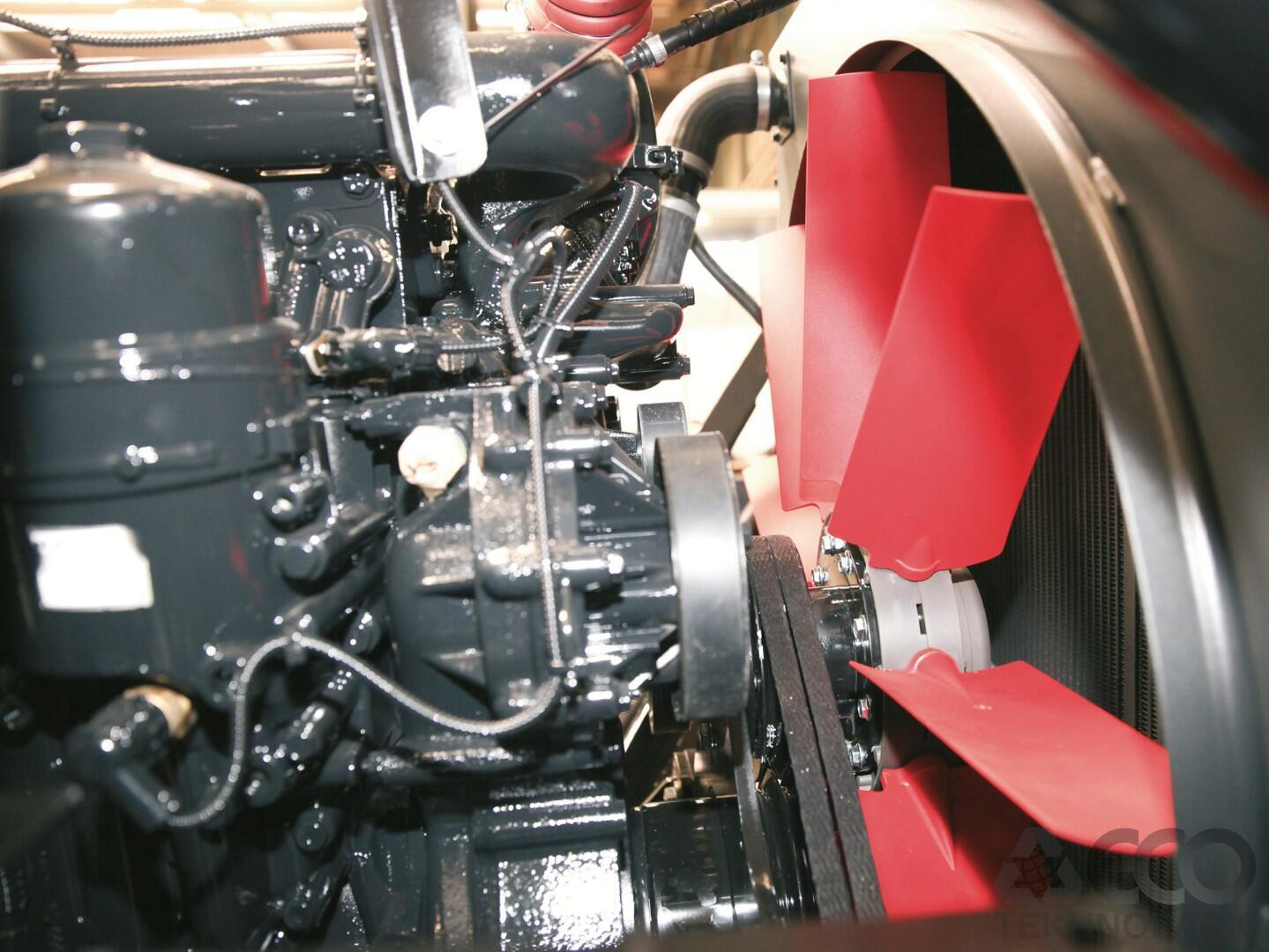

| Reversible Fan |

# |

° |

| LED work light |

# |

° |

| Water Spray System |

|

° |

| hydr. foldable extended hopper |

# |

° |

| hydr. or manual foldable extended side walls |

# |

° |

| Прицепное кольцо |

|

° |

| Special Paint |

|

° |

| Biological Oil |

|

° |

| Diesel Particulate Filter |

|

° |

| Soundproofing Package |

|

° |

° - option

# - can be controlled by remote control.

| Name | Meaning |

|---|

| Transport Dimension (l/w/h) (mm) | 9950*2500*4000 |

| chassis | 2-axle-central carriage, for 80 km/h according to |

| Permissible Total Weight (kg) | 19.000 |

| Engine | |

| Manufacturer | MAN |

| Type | D2676 LE 140 / D2676 LE 139 |

| maximum Performance (kw/HP) | 353/480 / 382/520 |

| Emission | EUROMOT lV |

| Rotor | |

| Weight equipped (kg) | ~1300 (SHARK I) / ~ 1750 (SHARK II) / ~ 2000 (SHARK III) |

| Loading receiving window (H*W) (mm) | 900*1450 |

| Diameter (mm) | 1000 |

| Flails (pc) | 48 (Shark I) / 16 (Shark II) |

| Changeable tips (pc) | 32 (Shark II) |

| Milling Strips (pc) | 8 (Shark I) / 12 (Shark II) |

| Flail weight (mm) | ~ 3,5 (Shark I) / ~ 23 (Shark II) / ~ 23 (Shark III) |

Линия производства RDF-топлива

Линия производства RDF-топлива  Дробильно-сортировочная установка мобильная

Дробильно-сортировочная установка мобильная  Вертикальный паллетообмотчик BKS K1100

Вертикальный паллетообмотчик BKS K1100  Вертикальный паллетообмотчик BKS K1100M с Е-платформой

Вертикальный паллетообмотчик BKS K1100M с Е-платформой