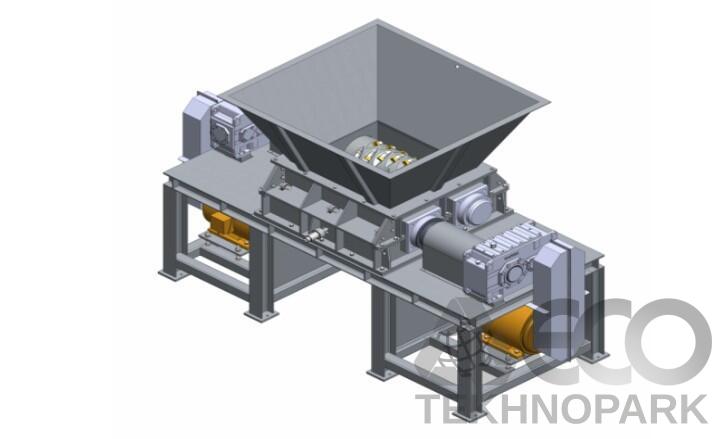

A pre-shredder (pre-crusher) is suitable for the early shredding and working as a debaler of particularly bulky or voluminous materials in bales. One typical example would be disintegrating plastic film in bundles at the beginning of a recycling line. The benefits of preshredder includes wear-off reduction to the proceeding machines and relieving the workload.

Applications:

- A mixture of domestic and industrial waste

- Mattresses and textiles

- Pressed bales of scrap

- Plastic waste and plastic rolls or in bales (e.g. PET bottles, PP bags, plastic films and compressed plastics)

- End-of-life car and truck tires

Pre-shredder Features:

- High stability and quiet.

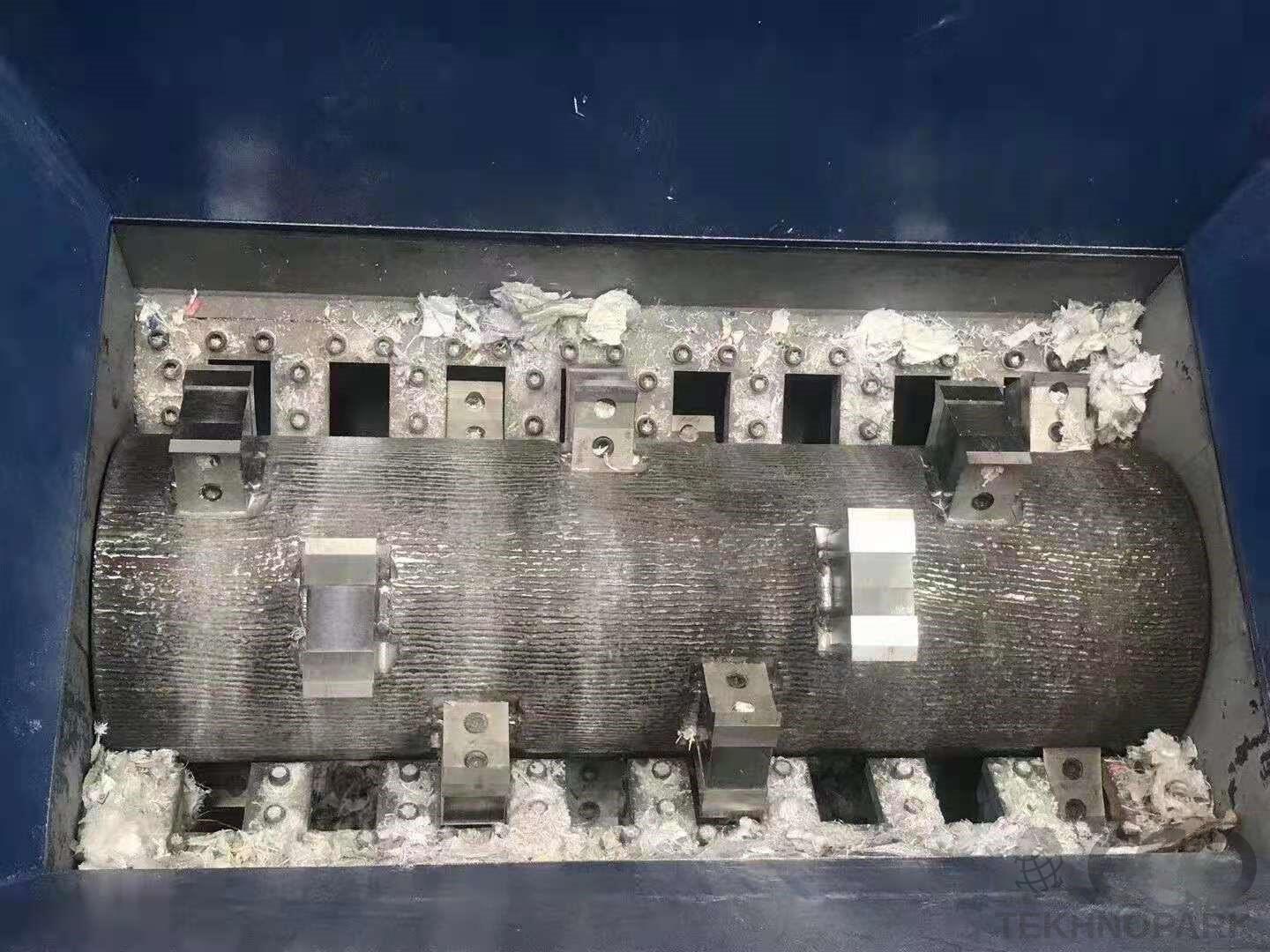

- Enlarged tooth(knives) for increasing contact surface.

- Hardfacing shaft is resistant to impact and abrasion.

- Discharge stones, sands and small metal parts, minimizing wear and tear costs.

- Auto-reverse system re-orients shredder rotor’s direction when motor overload and material jam.

Pre-shredder is composed of a large diameter rotor, large size tooth and high torque motor. Other than featuring rotor and tooth, the low-speed rotor is mainly suitable for handling bulky and non-homogeneous materials such as agricultural films, woven bags and textiles in rolls or bales.

This debaler is allowed to handle contaminated materials with a high percentage of metal parts or sands. However, the size of the output materials is about palm size. Thus, pre-crusher is generally used as a debaler, a preliminary size reduction or primary treatment.

| Mode | PC6100 | PC6130 | PC8130 |

|---|

| Rotor (mm) | 600 | 600 | 800 |

| Width (mm) | 1000 | 1300 | 1500 |

| Power (kw) | 45 | 55 | 75 |

| Capacity (Kg/h) | 500 | 1000-1500 | 2000-3000 |