Raw materials: granite, limestone, basalt, shale, pebbles, ore, steel slag, quartz, silica, gypsum, volcanic rock, marble, river stone, calcite, dolomite, coal gangue, tiles, concrete hollow blocks, cement clinker etc.

Application: minerals and hard rock crushing, construction waste recycling, slag processing, highway and tunnel construction, water conservancy, metallurgy, chemical industry etc.

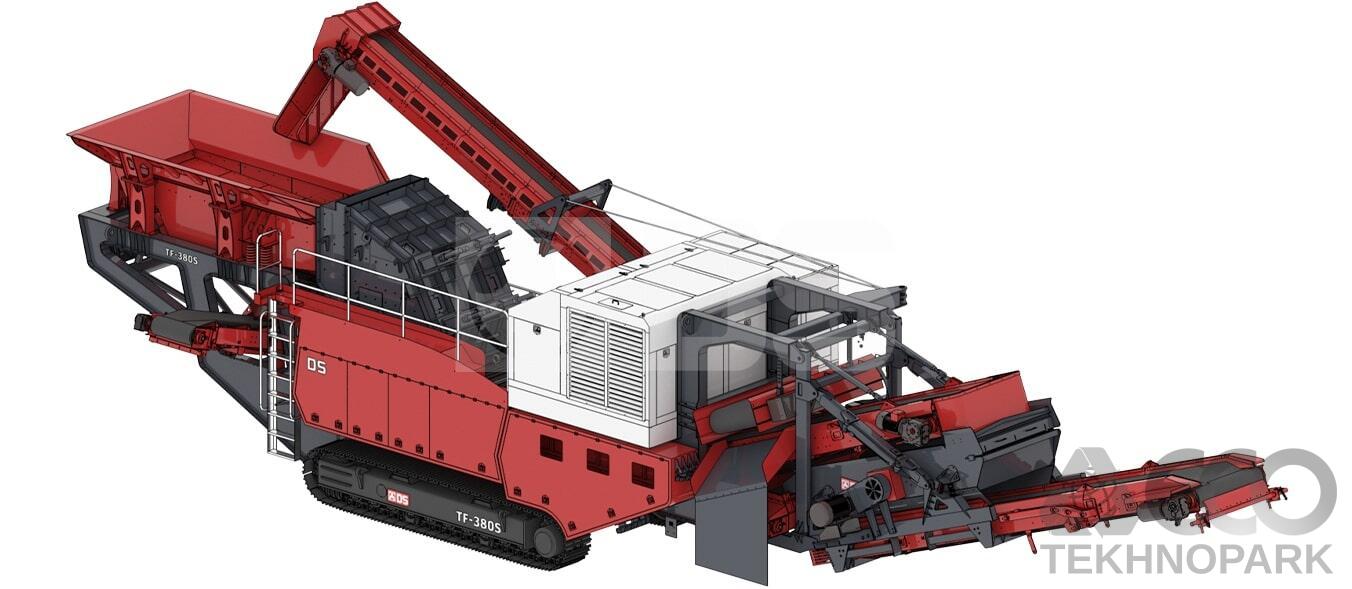

The TAFS series tracked crushing and screening plant is an integration of new type energy-saving, efficient crusher in the international advanced level. Modular design, excellent combination, intelligent wireless operation, low cost and efficient operation. We put the site design, environmental protection, easy to transport, and saving energy as the primary problem to be resolved, providing customers with the best technology of crushing solution.

With high performance, high reliability and attractive appearance, the tracked crushing and screening plant has reached the international advanced level. We can design the primary crushing, secondary crushing, tertiary crushing and combine them according to customers' requirement.

| TAFS270 | TAFS380 |

|---|

| Max. feed size, mm | ≤400 | ≤500 |

| Capacity, t/h | 100-200 | 200-300 |

| Installed power, kw | 281 | 365 |

| Generator set, kw | 75 | 90 |

| Working dimension, mm | 15400x10400x7200 | 18330x10400x7200 |

PET bottle washing line

PET bottle washing line  Tracked jaw crusher TJC

Tracked jaw crusher TJC  Установка дробильно-сортировочная на гусеничном ходу

Установка дробильно-сортировочная на гусеничном ходу