GEOMEMBRANE: WHAT IT IS AND HOW IT IS USED

Geomembrane HDPE and LDPE is a synthetic material resistant to decomposition, rotting, and corrosion. It is manufactured from polyethylene, which is divided into two main types: high-density polyethylene (HDPE), produced using low pressure, and low-density polyethylene (LDPE), produced using high pressure. It is used as a waterproofing material for constructing reservoirs, canals, manure storage facilities, and MSW landfills. The membranes are also effectively used for waterproofing roofs and foundations in industrial and residential construction.

- HDPE Geomembrane features high strength and chemical resistance, making it suitable for use in municipal and industrial solid waste landfills and for constructing water reservoirs.

- LDPE and LLDPE Geomembrane retains elasticity at low temperatures. It is used for construction on weak subgrades, in seismically active areas, and for waterproofing underground structures.

- Reinforced Geomembrane includes an additional layer of geotextile that protects it from damage by rock fragments, roots, and gravel. It can be reinforced on one or both sides. The thermal bonding of the membrane and geotextile enhances strength characteristics.

- Two-Color Geomembrane is differently colored on each side (e.g., blue on one side, green on the other), allowing for its wide use in landscape design.

HDPE, LDPE, LLDPE GEOMEMBRANES - KEY ADVANTAGES:

- Operating temperature range from -40⁰C to +50⁰C

- Resistant to soil pressure

- Environmentally safe

- Resistant to aggressive environments

- Service life in soil from 30 to 80 years

- Resistant to distortion

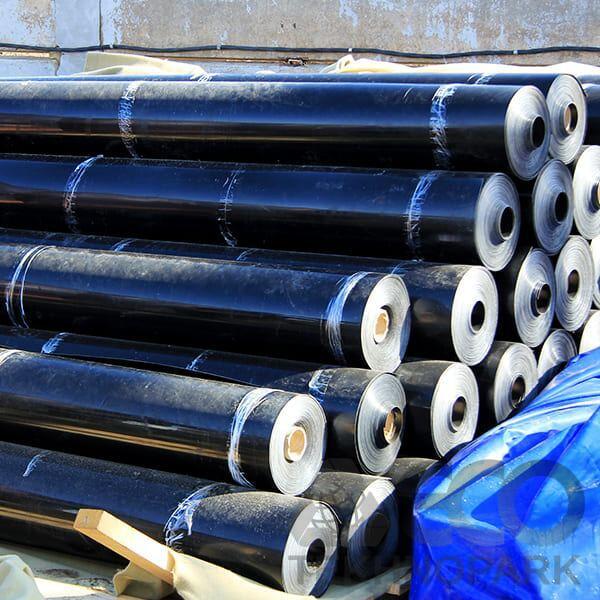

- Lightweight, easy to unroll and cut

GEOMEMBRANE PROPERTIES:

Geomembranes feature high anti-corrosion and waterproofing performance, resistance to most chemical reagents (suitable for storing liquids with pH from 0.5 to 14) and UV radiation. Their relative elongation of 450% to 700% allows for the successful installation of reliable anti-filtration barriers.

The geomembrane thickness ranges from 0.75mm to 3mm, depending on specific project requirements. Geomembranes are supplied in rolls with a standard width from 1.65m to 8m. The sheet length in a roll depends on the material thickness.

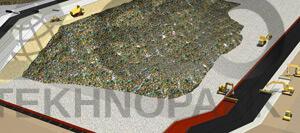

GEOMEMBRANE INSTALLATION TECHNOLOGY:

- Surface preparation for geomembrane installation: stump removal, clearing of shrubs.

- Surface leveling, excavation of a pit for an artificial reservoir.

- Placement and compaction of a sand sub-base, installation of a protective layer (geotextile with a thickness of at least 3mm).

- Distribution of geomembrane rolls across the construction site.

- Welding of geomembrane rolls using hot wedge or extrusion welding equipment.

- Checking the integrity of welds using air pressure testing or visual inspection.

- With a geomembrane width of 2m, the welding rate is 1,500 - 2,000 m² per day.

| Parameter name | Нормы для типа | | |

|---|

| LDPE 10803-020 (LDPE) | HDPE 273-83 (HDPE) | LLDPE |

| Geomembrane sheet thickness, mm | 0,75-3,0 | 0,75-3,0 | 0,75-2,0 |

| Geomembrane sheet width, m | | | |

| Geomembrane sheet length, m | no more than 8 | no more than 6 | no more than 8 |

| Длина листа, м | 50, 100 | 50, 100 | 50, 100 |

| Service life, years | at least 30 | at least 30 | at least 30 |

| Guaranteed shelf life, years | 2 | 2 | 2 |