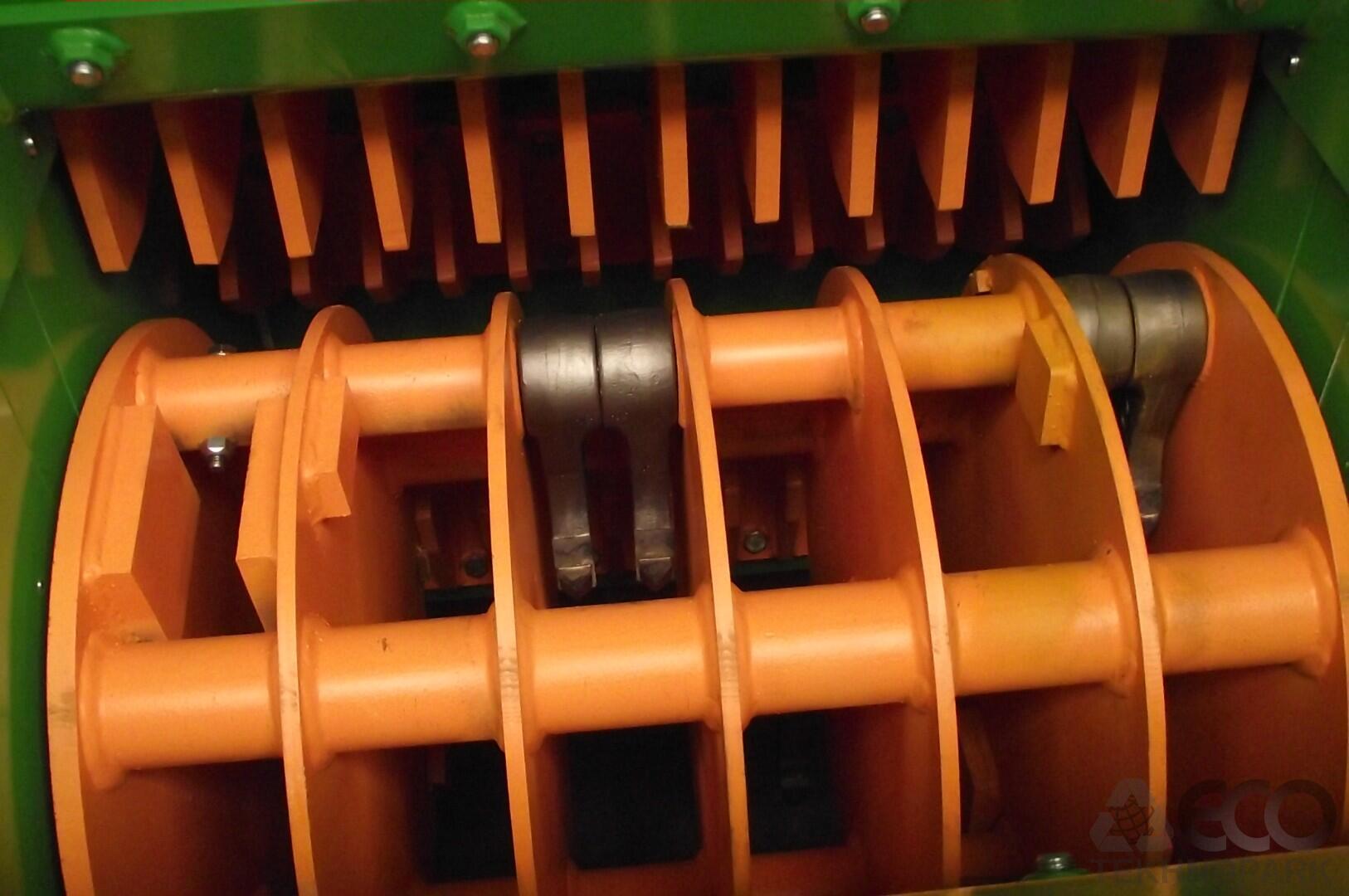

The heart of the stationary chipper is a cylindrical shredder rotor made of thick-walled steel discs welded together, between which 12 free-swinging, sickle-shaped flails operate according to the hammer-and-mill principles.

Its strength lies in uninterrupted, automated and continuous use. Combined with additional conveyor belts the whole process, including the undead and discharge, runs by itself.

The stationary shredder is suitable for working with the following materials:

- pre-crushed wood

- compost material

- bark

- peat

- is a substrate for biogas (for example, sugar beet; potatoes; onions; carrots; manure; grass and corn silage), as well as empty fruit bunches

Shredder Features:

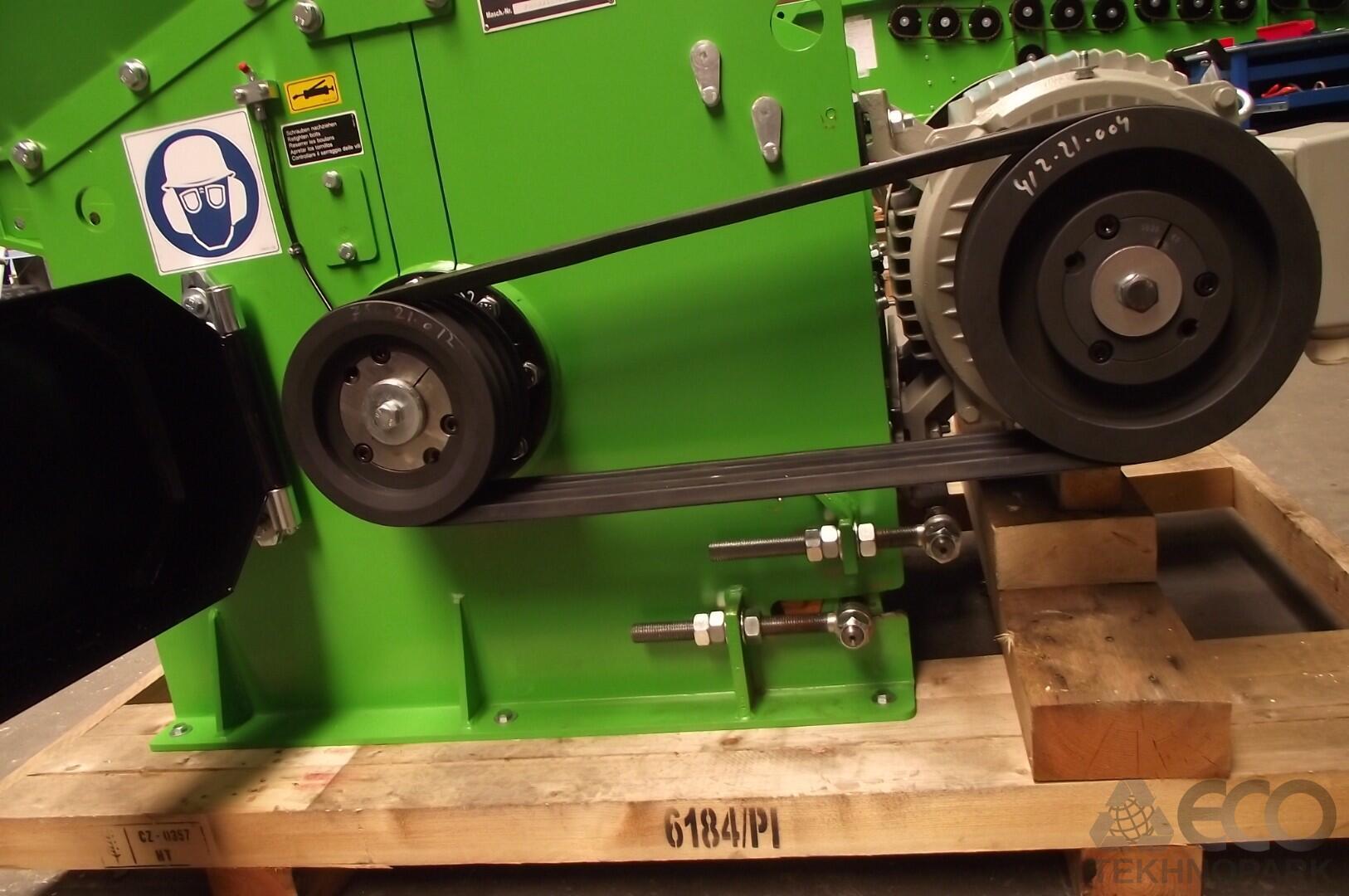

- 45 kW electric motor drive - Continuous duty operation

- Robust, compact design

- Narrow, freely-swinging hammers

- 3 individually replaceable breaker bars

- Final particle size adjustable manually via set screw

Clients are provided with: star-triangle switch, feeding conveyor, unloading conveyor.

| |

|---|

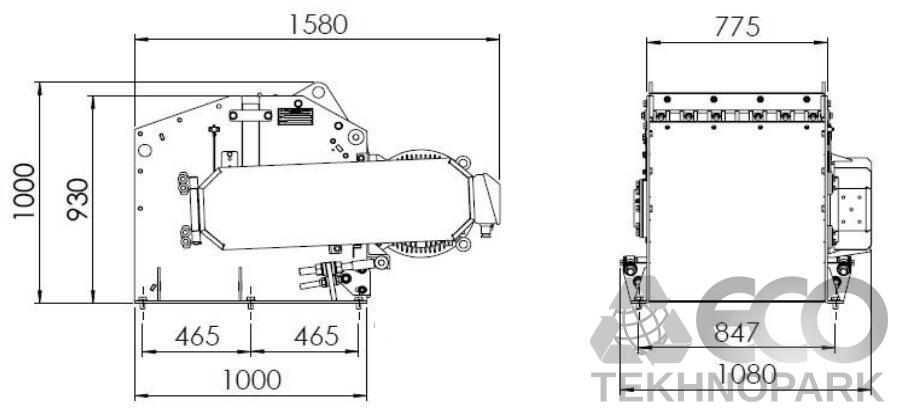

| Transport Dimension (LxWxH), mm | 1580x1080x1000 |

| Engine | |

| Operational voltage / frequency / amperage, V / HZ / A | 400 / 50 / 78 |

| maximum performance (kW) | 45 |

| Nominal rotation speed (rpm) | 1500 |

| maximum Torque (Nm) | 268,5 |

| Protection class | IP55 |

| Chassis | |

| Hole size of fixing screw | 847x465 (6 M20 screws) |

| Total Weight (kg) | ~1300 |

| Rotor | |

| Weight equipped (kg) | ~330 |

| Diameter (mm) | 775 |

| Rotation speed (rpm) | 2000 |

| Flails (piece) | 12 |

| Outputs | |

| Green Waste (m³/h) | 15 up to 30 |

| Pre-crushed old wood (m³/h) | 15 up to 25 |

| Bark (m³/h) | 15 up to 25 |

| Manure (m³/h) | 10 up to 20 |

| |

| |

| |

| |

T1500 Throughput 1500 kg/hour

T1500 Throughput 1500 kg/hour  Т500 производительность 500 кг/час

Т500 производительность 500 кг/час