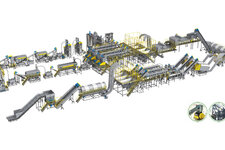

Solutions and equipment for automatic optical sorting of different types of waste

The use of the automatic material sorting equipment with optical recognition system allows for a multiple times faster sorting speed and material picking efficiency as compared to the manual labor. In addition, the ability to identify more than a thousand materials (by type, volume, colour and chemical composition) opens wide prospects for industrial application of these technologies.

The use of the automatic material sorting equipment with optical recognition system allows for a multiple times faster sorting speed and material picking efficiency as compared to the manual labor. In addition, the ability to identify more than a thousand materials (by type, volume, colour and chemical composition) opens wide prospects for industrial application of these technologies.

Our solutions are applicable in various branches of industry, thereby special attention is paid to intelligent, automated and precise sorting of renewable resources. These solutions cover a range of branches, including the secondary raw materials sorting, solid municipal waste sorting. The goal is to ensure stable and efficient recovery of various renewable resources with the simultaneous reduction of the carbon emissions in the cities due to efficient sorting and recycling.

Equipment for optical waste sorting is based on several technologies: artificial intelligence, near infrared range, colour spectrum sorting, laser sorting, and is applied to perform a wide range of sorting tasks. Optical sorters (scanners) can efficiently sort and extract high-quality materials from different sources, as well as provide real-time monitoring and analysis of the sorting data, which allows to develop a closed system for management of big data on the resources.

Main technologies:

Sorting technology using artificial intelligence (Al) can ensure accurate identification of the materials. Lightweight precise industrial scanner models with a structured database of the large solid waste images allow to significantly increase the speed of calculations and support high-speed visual imaging of the conveyor belt at the speeds of up to 6 m/s.

Near infrared sorting technology (AI-NIR). AI NIR sorting technology uses a combination of artificial intelligence and near infrared sensors to accurately identify raw materials by the material range, colour and appearance. It can also identify different forms of the same material.

MultiSensor fusion technology supports combinations of various sensors such as visible light, near infrared range, X-ray beams, fluorescent, laser, hyperspectral sensors and metal detectors. It uses fuzzy logic algorithms and deep neural networks to fuse heterogeneous data from multiple sources at the decision-making level.

Optical sorters (scanners) and sorting robots can work with all the recyclable types of waste generated by the modern world.

- extraction of high purity plastics such as PET, PP, PE, PC and PVC from mixed recyclable plastic waste. We can additionally sort plastics from the same material by colour, grade and type.

- sorting waste paper into different categories such as "yellow, coloured" waste (yellow cardboard, corrugated paper, honeycomb paper), white waste (book paper, office paper), other types of paper (cigarette packaging, medical cards etc.) and Tetra Pak carton.

- sorting and cleaning the scrap metal, including dismantling cars, used electrical appliances, batteries, electronic waste, etc.