Stepped grate furnaces (Pre-combustion chambers) for alternative fuel (RDF) co-processing in cement plants

These are specialized systems designed for the thermal utilization of low-grade alternative fuels, which are integrated into the clinker production process. The use of RDF fuel reduces the burden on landfills, lowers the carbon footprint, and helps in meeting target environmental standards.

These are specialized systems designed for the thermal utilization of low-grade alternative fuels, which are integrated into the clinker production process. The use of RDF fuel reduces the burden on landfills, lowers the carbon footprint, and helps in meeting target environmental standards.

What is a Stepped Grate Furnace (Pre-combustion Chamber)?

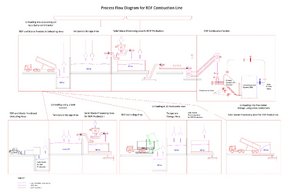

A stepped grate furnace is a module located upstream of the pre-calciner and the main rotary kiln. It is a combustion chamber designed for the staged feeding of alternative fuel (RDF) and the active supply of air to ensure stable and complete combustion, even for difficult-to-handle alternative fuels.

Key Features:

- Combustion of coarse and high-moisture RDF: Capable of processing RDF with fractions up to 150 mm and moisture content up to 45%, which is critical for reducing fuel preparation costs.

- Multi-stage air distribution: Primary and secondary air are supplied at different levels of the grate, ensuring gradual and controlled combustion.

- No moving parts in the high-temperature zone: This design minimizes wear and tear and simplifies maintenance.

- Full integration with the main kiln: Combustion in the stepped grate furnace pre-burns the RDF, and the resulting hot gas is fed directly into the pre-calciner and then the kiln.

Technology advantages:

- High RDF utilization rate, including complex waste streams with low calorific value.

- Minimal RDF preparation requirements, reducing both capital (CAPEX) and operational (OPEX) expenditures.

- Reduced load on the rotary kiln, extending its service life.

- Environmental efficiency: Improved temperature control and complete combustion lead to reduced emissions of CO, NOx, and unburned hydrocarbons.

- Modularity: The furnace can be retrofitted to existing production lines without requiring a radical reconstruction of the entire kiln system.

Application areas for stepped grate RDF furnaces

The stepped grate furnace (or pre-combustion chamber) is specialized equipment for the thermal utilization of low-quality RDF and other hard-to-process alternative fuels. Due to its flexibility and modularity, it is used in the following industries:

Cement Industry (Primary Application):

- Replacement of fossil fuels (coal, heavy fuel oil, gas) with RDF.

- Use in clinker kilns for the preliminary combustion of RDF.

- Can be adapted to existing production lines without a complete rebuild. Aligns with EU and Russian policies on CO₂ and waste reduction.

Waste Processing and Environmental Sector:

- Thermal utilization of the high-calorific fraction of MSW (Municipal Solid Waste).

- Installation at RDF production facilities.

- An alternative to traditional waste-to-energy plants, with directed thermal use in industrial processes.

Chemical and Petrochemical Industry:

- Disposal of organic, polymer, and petrochemical waste.

- Can be part of integrated solutions for handling hazardous waste.

Metallurgy and Building Materials Production:

- Use in shaft or rotary kilns for supplying RDF to metal reduction processes.

- Application in lime production and other mineral processing requiring high thermal loads.

Industrial Power and Cogeneration Plants:

- Integration into combined heat and power (CHP) systems for industrial needs.

- Use in closed-loop CHP solutions operating on RDF fuel