Film and thread-shaped waste recycling (plastic flakes and pellet production) line with a 500 kg/h output

Lines were supplied, installed and put into operation as a part of a Waste sorting plant, it is designed for plastic waste recycling and plastic pellet production

Description

The 1st area - Plastic flakes production line

The line was supplied, installed and put into operation as a part of a Waste sorting plant, it is designed for plastic waste recycling and plastic flakes production.

The plastic flakes production site is for secondary PET recycling (PET bottles, containers, other PET packaging) into plastic flakes at a processing line with a 500 kg/h output. The processed material is sorted PET packaging with significant (up to 20% by weight) contaminations (including bottle caps, neck rings, labels, glue).

The end product is clean and dry PET flakes 15mm in size. The content of the particles that are more than 15mm in size does not exceed 2%. PET flakes humidity is <1%. Impurity content: PVC - <0.01%, labels - <0.01%, glue - <0.07%, metal, wood, garbage - <0.01%.

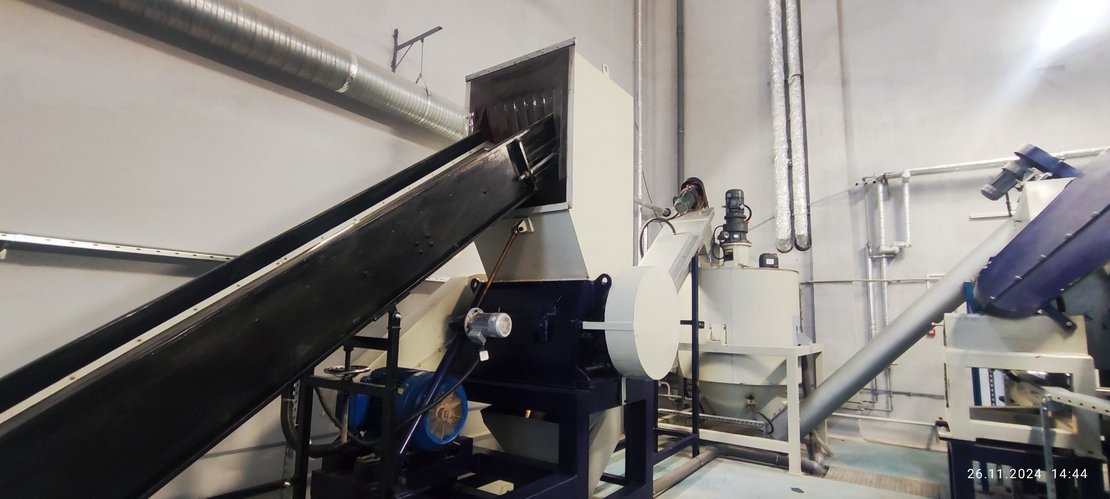

Composition of the line (shredding and cleaning area):

- Bales (packs) unpacker complete with a transporter - 1pc.

- Belt conveyor - 1pc.

- Label remover - 1pc.

- Metal detector - 1pc.

- Sorting table complete with a conveyor - 1pc.

- Crusher - 1pc.

- Screw feeder - 1pc.

- Hot washer - 1 pc.

- Screw feeder - 1pc.

- High-speed friction washer - 1pc.

- Flotation washer - 2pcs

- Screw loader - 2pcs.

- Water separator - 1 pc.

- Drying system - 1 pc.

- Zigzag separator - 1pc.

- Big bag packaging system - 1pc.

- Control cabinet - 1pc.

- Water purification system - 1 pc.

The 2nd area - Pellet Production Line

This is the second section of the integrated line for processing film and fibrous waste.

Composition of the line:

- Sorting station with metal detector, horizontal - 1pc.

- Belt conveyor - 1pc.

- Heavy-duty universal washing crusher / grinder - 1pc.

- Universal washing tank / unit - 1pc.

- Friction wringer (drum-type) with three centrifuges - 1pc.

- Friction washer (rotor-type) - 1pc.

- Friction wringer (drum-type) with three centrifuges - 1pc.

- Discharge / Unloading unit - 1pc.

- Dewatering press-agglomerator / extrusion agglomerator - 1pc.

- Single-stage PE/PP granulation line, water-ring pelletizing system, capacity up to 500 kg/h - 1pc.

- Centralized water cleaning / purification system, capacity 2.5 m³/h - 1pc.

The equipment of the line has all the necessary authorization documents, the line is supplied with marks on it, it has an intuitive system of control, visualization and recognition of all the operations.

Technical data

| Line output, kg/h | up to 500 |

| Power consumption, kW | 638 |

| Water consumption volume, t/h | 9 |